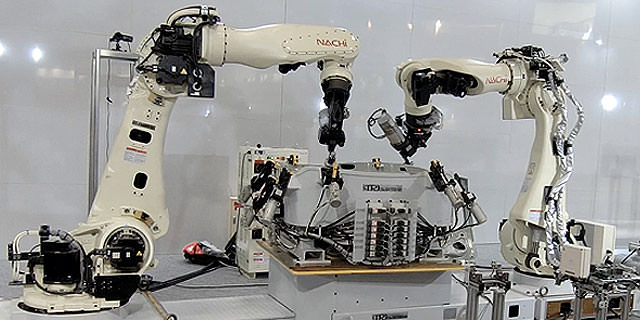

RHS is an abbreviation of Robot Hemming System

It is an indispensable system for the cars.

For example, look at the car's door. Edge of the steel plate is not seen at any door,

always decorated wrapping process. Conventionally, this process had been done with huge press machine or dedicated bending machine,

but a large space for the machinery installation is required, and also the cost is expensive. Press and bending machine have many demerits. So there had needs improvement.

TRI ENGINEERING focuses on hemming systems with robot to solve these problems.

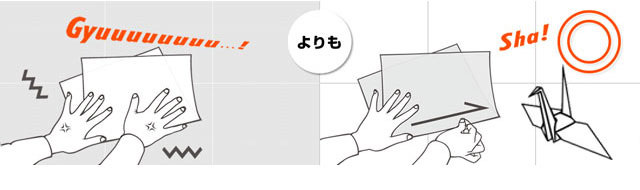

And mount the roller on the tip of the robot like the tip of a finger when folding ORIGAMI, pressed against the iron plate by high quality bending.

This is the method generates high quality in a small force by bending theory differs from the traditional press hem and the table top hem was born.

In 1991, this Robot Hemming System was developed first in the world, takes the same basic patent (retrieved 18 patents until 2013),

In 1992, Toyota Motor Corporation adopted the Robot Hemming System.

Currently, not all automotive manufacturers in Japan and overseas automotive manufacturers have adopted our RHS.

Also, in 2013, previously redesigned the mechanism and the roller pressurization method changed from hydraulic to servo controlled servo pressure hemming system release.

Robolution robots have a skilled, sensitive and smart machining continues to evolve further.